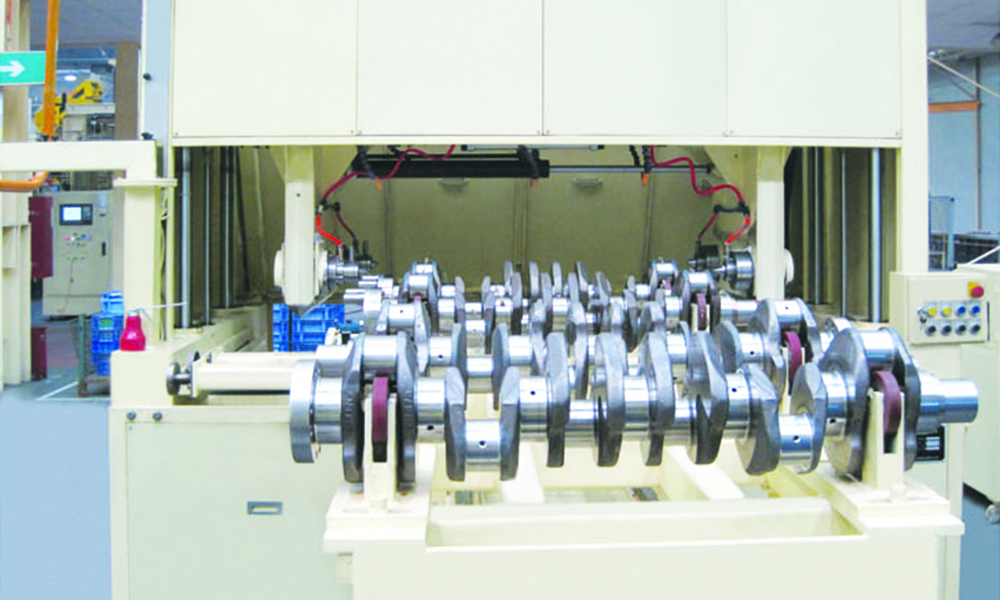

During operation,parts are fixed in the main axis and drive up/down by lifting device.

When parts merge into tank full of grinding media,parts rotate along its own axis and media tank move back and forth,thus achieve high effciency micro cutting.

Also adjusting rotary/linear movement speed, parts with different material/geometry may achieve optimal finisning quality.

Application:

Applied to all kinds of shafts,poles,covers parts surface treatment.Polishing,grinding,rounding and deburring without change parts original size and surface roughness.

Can also irnprove parts surface physical mechanical performance.

Remove surface remaining tensile stress,improve surface wear resistance and hardness.

|

Processing diameter |

≤320mm |

|

Processing length |

500~1200mm |

|

Working capacity |

2 |

|

Main motor |

5.5kw |

|

Media container motor |

7.5kw |

|

Hydraulic pump motor |

3.0kw |

|

Water purification motor |

0.8kw |

|

Dimension of machine(L×W×H) |

2750×1970×2920mm |

|

Electronic control cabinet size |

900×500×1800mm |

|

Water purification system size |

1700×1506×800mm |

|

Media container size |

2180×2200×1480mm |

|

Gross weight |

4500kg |