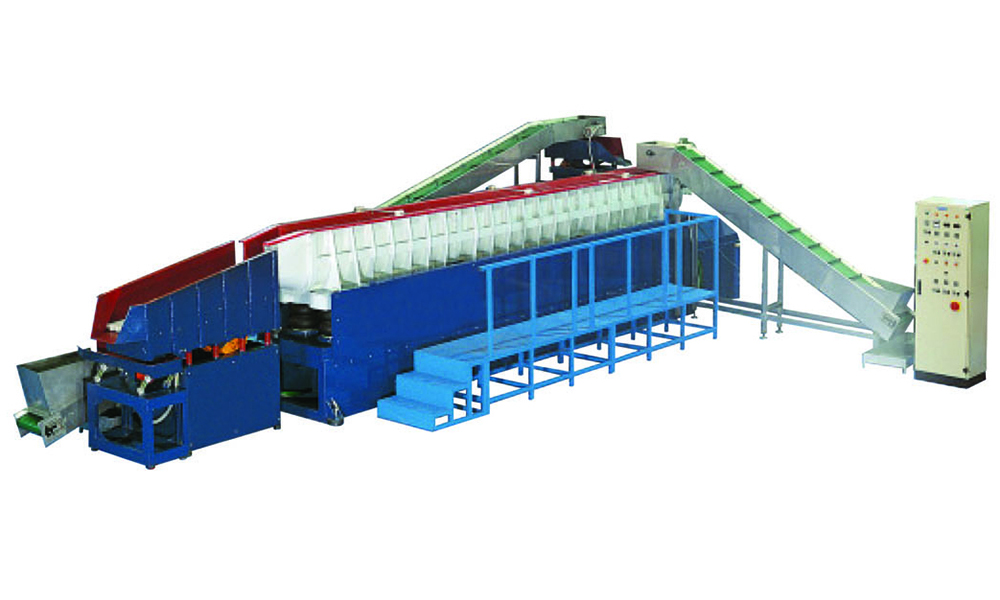

1. Linear type vibratory finishing machine combined all surface finishing process including deburring,polishing,clearing,de-oxidation and drying.

2. Linear type vibratory finishing machine comprised of media feeding system,linear processing chamber,central lubrication system for the turning over devices,media/part separation screen devices,rinsing﹠oiling device,worn out/undersize media separation device,media transportation system,watering/drainage system and central control system.All functions can be realized with PLC.

3. Advanced vibratory system, vibration parameters adjustable to optimal state.

4. Electronically controlled,demand oriented lubrication system for the turning-over devices.

5. Solenoid valves controlled water drainage system.

6. Watering,compound supplying,used water drainage,rinsing has realized automation.

7. Linear type vibratory finishing machine operated with 2-3 staffs can continuously run for 24 hours.

8. All cables connect to central control system through cable tray.

|

Model |

Capacity |

Working capacity |

Channel |

Motor |

Speed |

Weight |

Area L×W×H |

|

LTG6500 |

1460 |

900L |

6500×450×600 |

22.0kw |

1470r/min |

6300 |

9500×4200×2700mm |