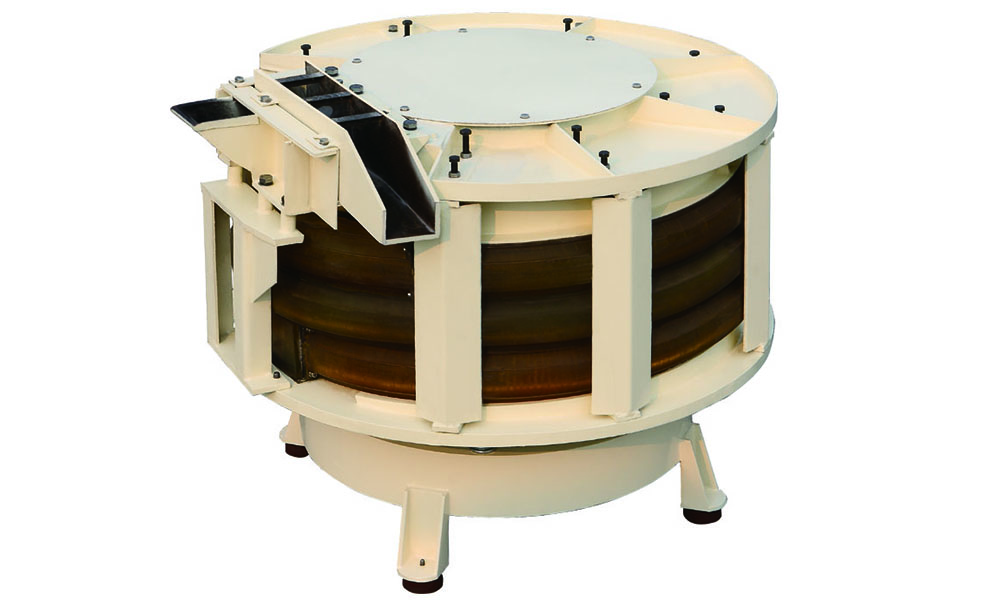

1.With feading entrance and exit area,easy to realize automation with conveyor belt and other systems.

2.Spiral tube with durable PU lining.

3.Overall length of spiral tube 18m,with high conveyer speed,can significantly improve processing capability.

4.Parts within spiral tube forced flow up and down,easy to realize heavy grinding performance.

5.Able to process delicate part without scratching.

6.Able to see observe how part flow through semitransparent spiral tube.

7.Processing time adjustable.

8.Space saving and compact design compared with other fine grinding process.

9.Spiral tubes can be easily disassembled and cleaned.

|

Model |

Capacity(L) |

Max overall dimension(mm) |

Machine height(mm) |

H1 |

H2 |

D(mm) |

Motor |

Weight |

|

LZG170 |

170 |

1453 |

1300 |

1210 |

1080 |

φ105 |

5.5 |

1200 |