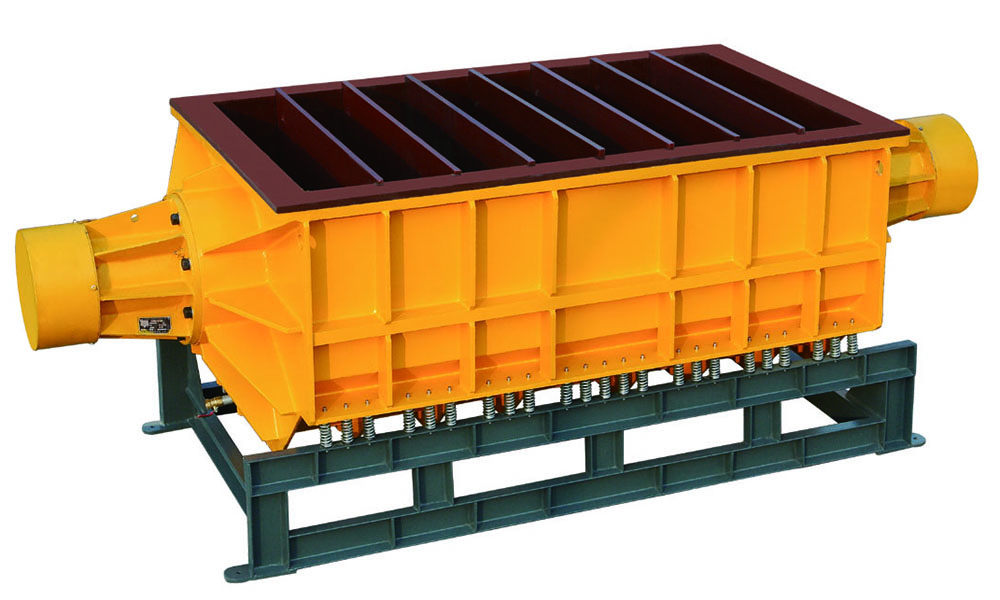

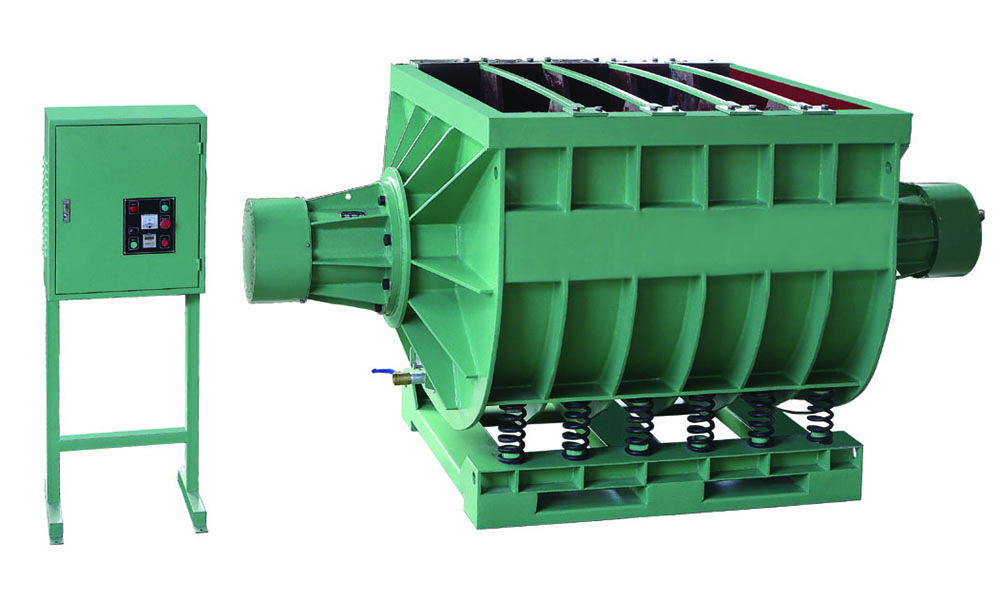

1. Apply dividing bulkheads to create independent treatment areas inside the tank,possible to process delicate components or components of different lots.

2. Realizing semi-automation through electronic controlling system and greatly improve work efficiency in stone surface finishing.

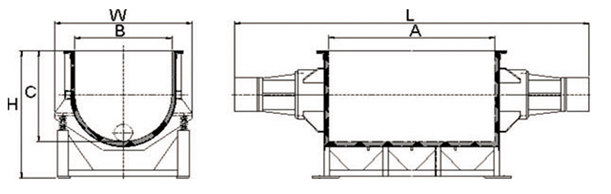

3. Steel vibrating tank lined with polyurethane.

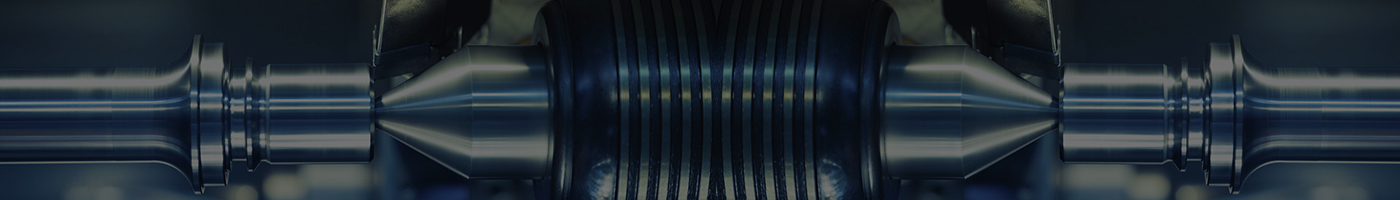

4. Two vibrating motors fixed sideways,equipped with adjustable weights,providing stable vibratory force.

Application:

Engine housing,engine shell,marble sheets and chassis parts etc medium to large size components surface treatment.

|

Model |

XZG(B)500 |

XZG(B)900 |

XZG(B)1200 |

XZG(B)1800 |

XZG(B)2800 |

|

Total volume(L) |

500 |

900 |

1200 |

1800 |

2800 |

|

Max overall dimension(mm) |

2670×1000×985 |

2700×1050×1100 |

3000×1050×1100 |

3500×1336×1256 |

3300×1830×1740 |

|

Chamber length(mm) |

1310 |

1200 |

2000 |

2000 |

1580 |

|

Chamber height(mm) |

700 |

850 |

850 |

940 |

1270 |

|

Chamber diameter(mm) |

690 |

900 |

750 |

1120 |

1500 |

|

PU Lining thickness(mm) |

25 |

25 |

25 |

25 |

25 |

|

Power(kw) |

2.2×2 |

4.0×2 |

4.0×2 |

5.5×2 |

9.0×2 |

|

Weight(kg) |

700 |

900 |

2100 |

2800 |

4000 |